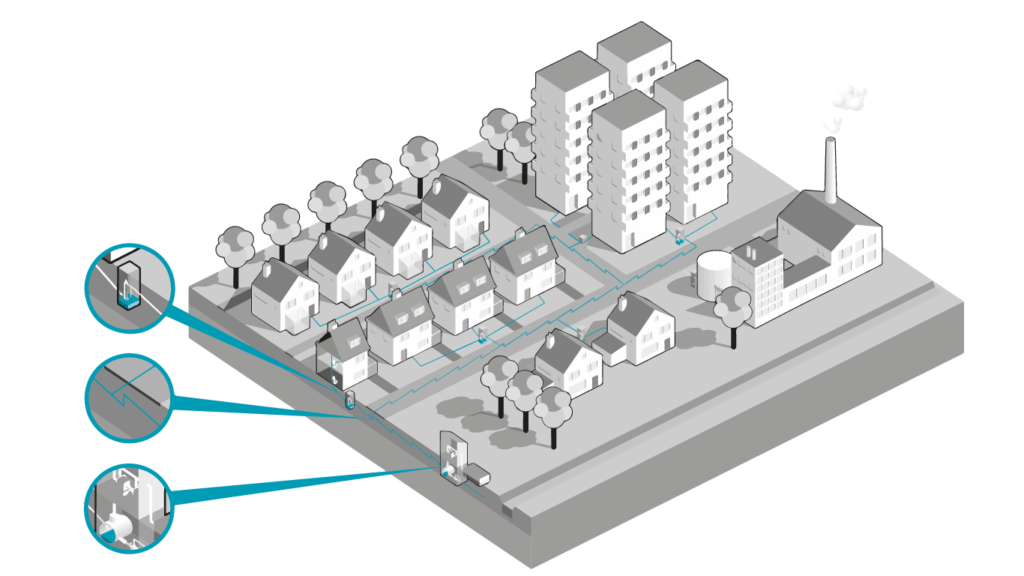

Qua-vac has developed a sustainable sewerage system called Vacuflow®. This sewage system is unique because, beside the vacuum station, it fully operates without the use of electricity. In addition, it has a long lifespan and low maintenance costs. Vacuflow® is applicable in many areas but is most of value in places where construction needs to be brought to a minimum.

What is Vacuflow®?

Vacuflow® is an innovative sewage system of great value in places where construction work is not (or barely) possible, like mountains or historical places. Hereby, Qua-vac realizes very limited drilling, so the architectural structures stay intact.

How does Vacuflow® work?

The Vacuflow® system basically consists of three elements:

- A collection chamber with interface unit

- A vacuum piping

- A vacuum station

Vacuflow® works with a collection chamber, a vacuum piping transport, vacuum station and vacuum tank. In that precise order. Sewage flows by gravity into a collection chamber, which stores the sewage. When the level of sewage rises to a high level, the air and sewage will be drained into the vacuum network. A float activator ensures that this ‘high level’ is reached. Good to know, that in the collection chambers, no electricity is involved.

Once the sewage has entered the network, the transport continues through the piping system. Another great advantage of the Vacuflow® is that this vacuum sewerage system can be installed in shallow trenches. The sewerage system can be laid at a depth of 80 – 120 centimeters.

When the sewage reaches the vacuum station, it ends up in the vacuum tank via the pipe network. Optionally, a sewer management system called Vaculink can be installed on the vacuum tank and on the collection chambers. This can monitor the whole system. How high the water level is, whether there are problems and so on.

Sewerage management with Vaculink

Vaculink always provides 24/7 insight into the system, real-time data and the current water level. But, in case of any problems: quick signaling, specific indication where the problem is located and alarm notification via SMS or email. In addition, the web portal can be configurated just the way you like!

- Online webportal

- All data 24/7 easily available

- User defined configuration

- Alerts via SMS or e-mail

The benefits of Vacuflow®

- Environment friendly

- Low maintenance

- Simultaneous air and sewage transport

- Only uses electricity at vacuum station

- Unique patented air/water venturi suction device (no H2S)

- Highly reliable system through level float device

- Standard manual bypass suction device

- Collection chamber with restore function

- Resistant against chemicals and corrosion

Optional benefits:

- Alarm notification with Vaculink

- Station, valve and high level monitoring

Method Vacuflow®

Sewage flows by gravity into a collection chamber. This collection chamber stores the sewage for a short time, with reserve storage availability. When the level of the sewage inside the collection chamber rises, a starter valve activates the vacuum piston valve to open which allows the content together with air to be drained into the vacuum network. This system has the advantage that more properties can be connected to one collection chamber. The mechanisms in these collection chambers work pneumatically / mechanically, which has the advantage that no electricity is needed.

The pipe network consists of PVC or HDPE pipes. A central vacuum station keeps this pipe network under negative pressure. Due to their small diameter, the pipes can be laid at depths of 80 to 120 centimeters under the ground surface. The addition of air makes the wastewater lighter, which leads to higher transport speeds. The pipe network is laid in a ‘saw tooth profile’. Within this profile, a mixture of wastewater and air from the collection chamber is transported to the vacuum station.

The waste water from the collection chamber ends up in the vacuum tank via the pipe network. The vacuum in the tank is generated by vacuum pumps. The extracted air can, if necessary, be purified through a filter. The level in the tank is measured with a Radar level measurement. At a high level, the pressure pump (s) starts and the waste water is transported to a sewage treatment plant or discharge point in the area. The discharge pump (s) stop at a low level.

Qua-vac has an extensive network of Vacuflow® distributors around the world as well as a large number of design and construction channels in European countries.

Get to know more about Vacuflow®? Get in touch

Is your company curious about Vacuflow®? Or would you like to make an appointment with us? Please get in touch through our contactform or speak with us personally by the phone. You can reach us at +31 (0)36 54 61 999 or by sending an email to info@quavac.com. We provide you a full service.