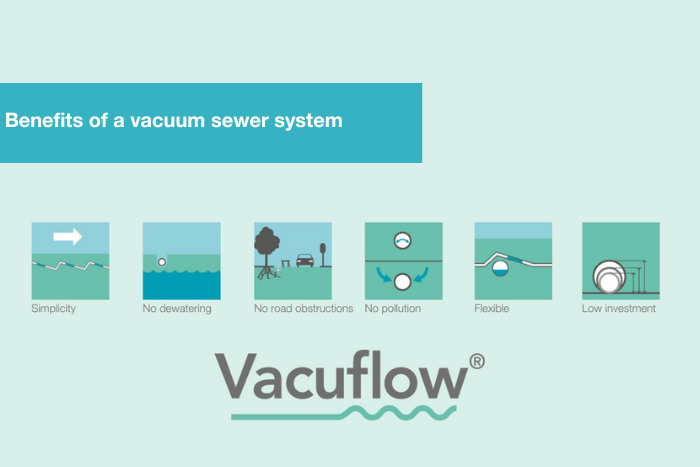

Vacuflow® vacuum sewerage has many benefits comparing to traditional sewerage. It is an easy to maintain and sustainable system. Furthermore it is less expansive and can easily be expanded.

Efficient and sustainable

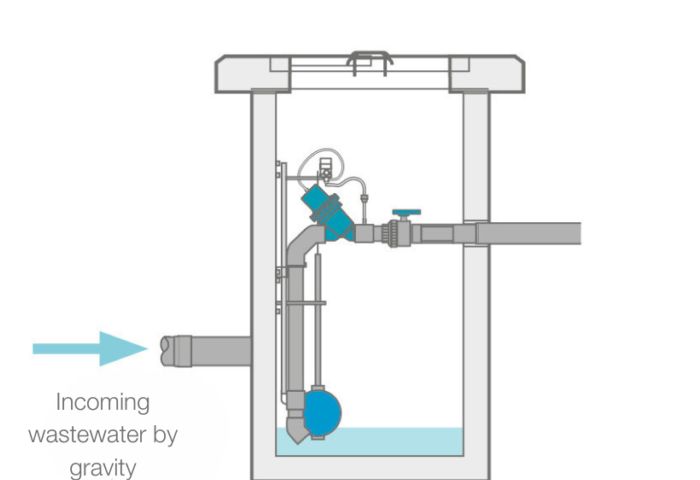

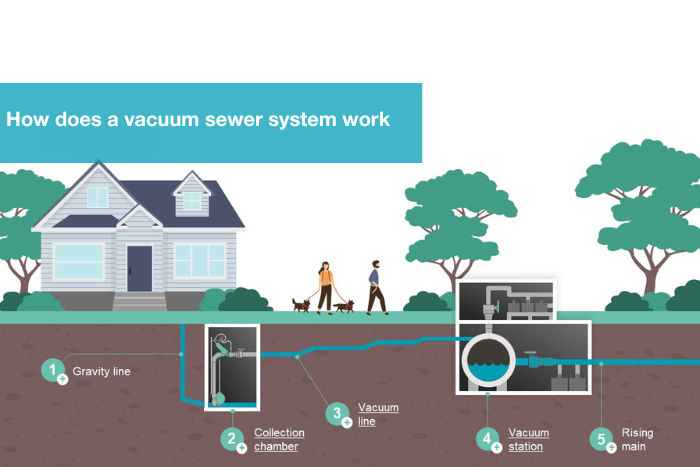

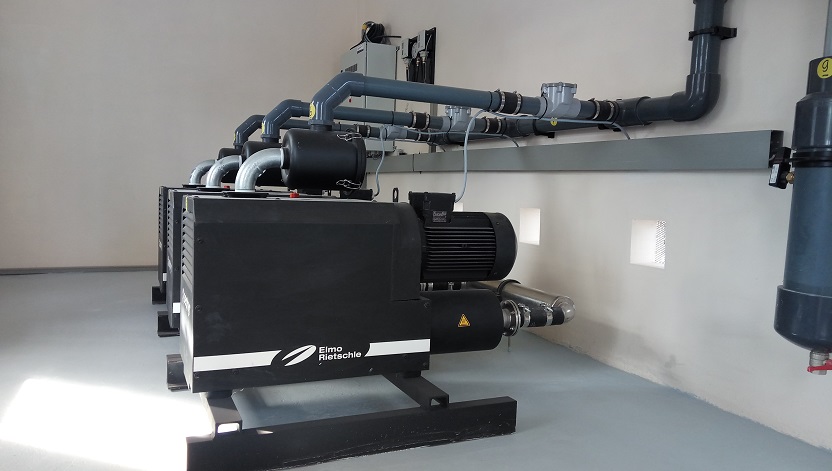

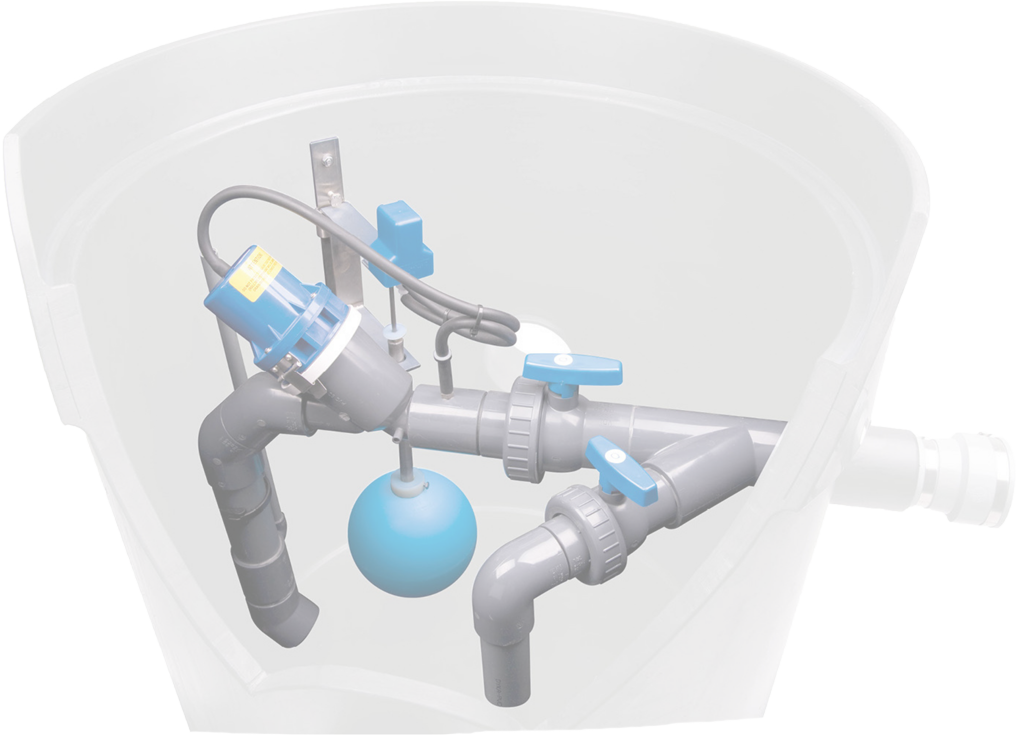

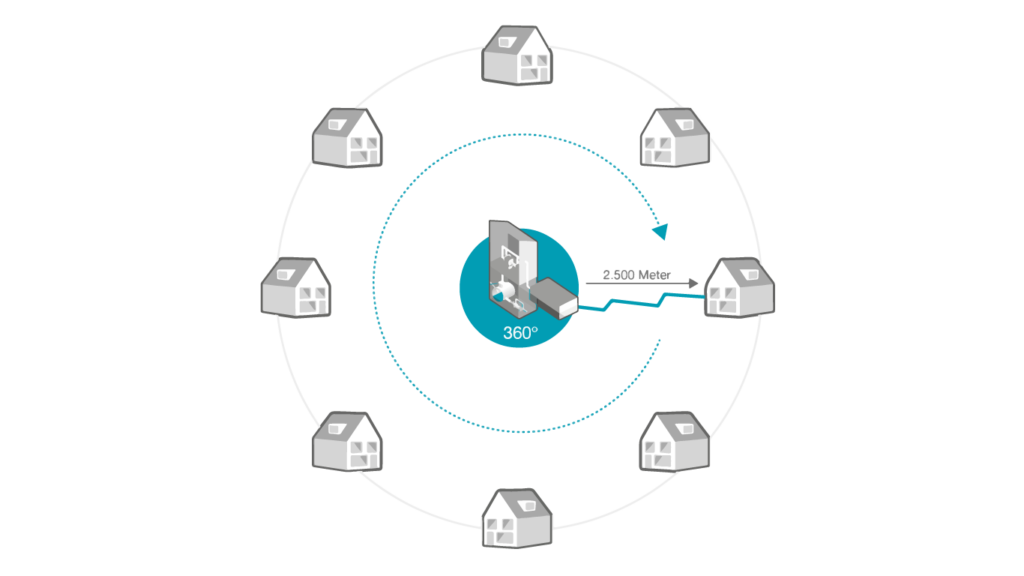

The Vacuflow® system is a clean and highly efficient system for environmentally acceptable sewerage disposal. Compared to traditional sewerage systems, the construction and installation of a vacuum sewerage system is considerably simpler and cheaper.

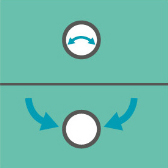

In addition, Vacuflow® is easy to maintain. It operates in a leak-proof vacuum network. Because of this, the environment will benefit too. No sewage can escape and pollute surrounding areas.

Vacuflow® applications

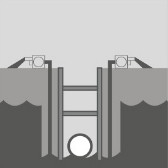

Field experts agree that in many applications, the Vacuflow® system is a better and cheaper alternative to conventional sewerage systems. The vacuum system is perfect for a wide range of applications, particularly where expensive and big construction work is to be avoided.

Ideal locations for vacuum sewerage systems are flat areas with high ground water table, sea side areas, environmentally sensitive areas, rocky areas, islands, artificial islands and areas where there is not much space for installation of a sewerage system.

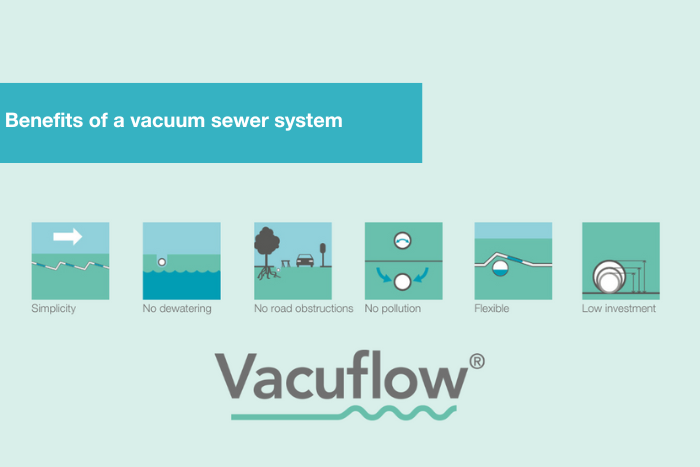

The benefits of a Qua-vac Vacuflow® system

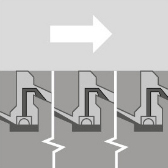

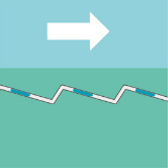

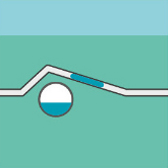

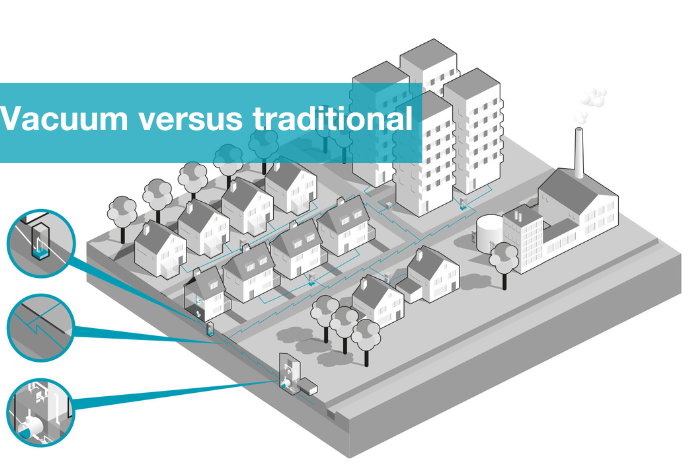

Traditional vs Vacuflow®

Traditional

Vacuflow®

Traditioneel

Vacuflow®

Curious about Vacuflow®?

Check the full technical operation and specifications of our Vacuflow® system.

Vaculink sewerage management

Vaculink is the online datatool, that supplies realtime data, 24/7. Online and user friendly!

Qua-vac is globally oriented and has Vacuflow® agents all over the world. Therewith we offer a wide range of design and construction channels in European countries.

Casestudy Stadslandsgoed de Kemphaan Almere

“Due to an increase in the number of facilities, the current capacity was no longer sufficient. We opted for vacuum sewerage from Qua-vac, because it fits well in our green sustainable concept. It is quickly installed, relatively simple and has little impact on the environment. ”

– Municipality of Almere