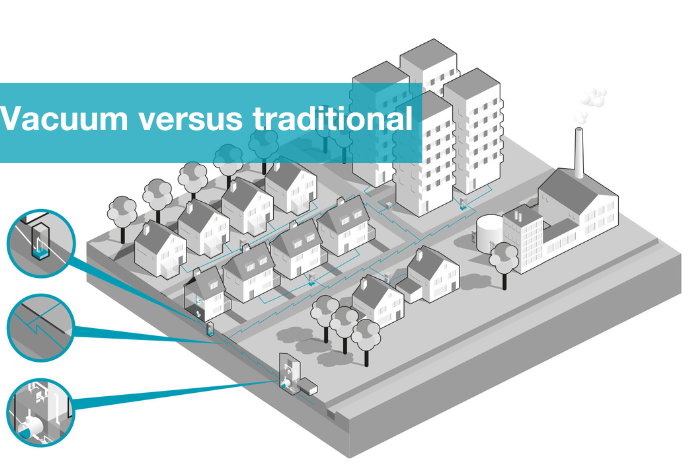

The comparison between a complex gravity sewer system and a simpler vacuum sewer system reveals several advantages. Gravity sewers often require a lot of materials which are costly to install and maintain, the expenses are associated with extensive excavation and trenching. On the other hand, a vacuum sewerage system offers simplicity by allowing shallow trenching, resulting in significant cost savings and reduced installation time.

No dewatering

Dewatering is another challenge when excavating in areas with high water tables. The process of removing water and stabilizing trenches can be complicated and time-consuming, adding to the expenses. Vacuum sewer systems eliminate or minimize the need for dewatering and trench stabilization procedures.

No road obstructions

In terms of road obstructions, gravity sewers with wide and deep trenches can render roads impassable for pedestrians and vehicles for extended periods. Additionally, trees and landscaping may suffer severe damage. In contrast, vacuum sewer systems utilize small diameter mains that are installed just below the frost level, enabling shallow and narrow trenching. This approach minimizes construction time and reduces disturbances to the environment.

No pollution

Pollution is a significant concern when using gravity sewers, as exfiltration can contaminate surrounding water sources such as lakes and rivers. Vacuum sewer systems, however, offer a fail-safe solution. They have been field tested and operated under vacuum conditions, ensuring that in the rare event of a broken main, infiltration can be easily detected, while exfiltration never occurs.

Higher flexibility

Flexibility is another advantage of vacuum sewer systems. Unforeseen obstacles, like water or sewer mains, large rocks or tree roots, often result in costly modifications and rerouting of lines in gravity sewers. In contrast, the flexibility of a vacuum systems allows for easy passage over, under, or around such obstructions, minimizing delays and eliminating additional expenses.

Lower costs

The investment required for gravity sewers is usually high, with large-diameter concrete or vitrified clay pipe mains ranging from 200 mm to 400 mm. These materials incur significant costs, along with excessive labour costs. In contrast, vacuum sewer systems utilize smaller-diameter PVC or HDPE pipes ranging from 90 mm to 200 mm. The labour and material costs associated with installing vacuum piping are dramatically lower compared to gravity sewers due to the reduced labour and trenching requirements for smaller-diameter vacuum mains.

About Qua-vac

With more than 50 years of experience, Qua-vac is a leading expert in sustainable vacuum technology and wastewater collection. We have divided our experience into three divisions: Infra, Marine, and building. Our mission is to transport and collect wastewater through sustainable vacuum sewage systems and new sanitation, worldwide. Qua-vac is the one-stop shop for all vacuum sewage and waste systems.

Qua-vac is the exclusive and official distributor of Evac Oy Benelux. Evac Oy is the world leader in sustainable wastewater treatment systems for the marine.